Part of the QA procedure for the MechBoard64’s (link) includes testing the keyboards in a real Commodore 64. Doing it this way calls for a lot of power cycles, cartridge swaps for testing keys, plugging and unplugging of the keyboards etc. I therefore use a motherboard that is not too precious to me. However, these machines eventually die and I was therefore on a quest for a new machine. During the hunt, I accidently stumbled across a machine that I thought would suit the purpose perfectly: yellowed case, broken keycap stems, missing keycaps, modified motherboard, missing SID etc. This was all based on the asking price… However, when I got the machine it turned out to be an Assy 250469 Rev. 3 machine in absolutely mint condition!! As in really perfect condition. And it also had a PCB color that I did not have in my collection yet! No yellowing, perfect case, no hardware modifications, all the right chips were soldered directly to the motherboard and it even had a very nice metal RF shield.

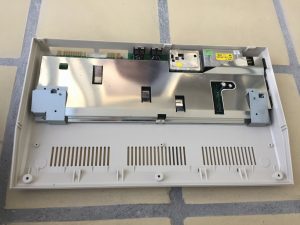

Here are some images of the machine.

So I’m still looking for a machine that I can use for my tests as this baby is going to be stored and kept as part of my collection! More images of the machines can be found here (link).

© breadbox64.com 2019

What causes your motherboards to fail? Do they short out or does an old capacitor fail? Something else? Whatever way they fail, keep them around. A local “Maker-style” hobby workshop might have an EE that would be able to troubleshoot it.

Hi Kriston, the motherboard that failed and needed replacement was actually ‘falling apart’ which caused it to fail 🙂 It wasn’t the chips that failed, but the traces on the motherboard that eventually had enough. The motherboard had been repaired a lot and quite a few parts had been exchanged to keep it going (power switch, cartridge port, capacitors, RAM chips, MPU, both CIA’s, VIC-II etc.). However, the continuous rough handling from swapping test carts, endless power cycles, changing of keyboards inside the machine (even though I use an extension chord) eventually made the copper traces brittle. If I added the slightest amount of pressure on it, it would go black on me.

After about 10 hours of faultfinding, replacing IC sockets and tracking broken trace(s) I finally decided to let it go… It had had a good life for more than 30 years. Given endless hours of joy to its owners. It is now resting in a peaceful corner of the garden with a small sign on top stating that it will never be forgotten…